This is the second brew day for this style of beer, so if you haven’t, make sure to read part one first.

Alright! 48 hours have elapsed since I inoculated the wort with the lacto culture andddd…..

The wort definitely has something going on. I can’t be completely sure that it’s a  successful lacto takeoff because I’m not about to send a sample to a lab but:

successful lacto takeoff because I’m not about to send a sample to a lab but:

- It was boiled for 15 minutes prior to incubating

- It’s been covered in plastic wrap, and a lid, and in an oven, undisturbed

- It sure smells sour

I tried a few methods of getting some ph strips but as I’m not willing to drive all the way to the Science Store to drop $6 on a pack of strips so I can use two of them, I wasn’t successful in time, but this definitely smells sour so I think it’s a sure thing. I’m feeling very weary of Kellin’s warning at the brew shop, so I give it a lot of deep, thoughtful sniffs. It smells super weird, to be sure, but I’m not really getting vomit-y butyric acid smells, so I think we’re good. It smells like malt and, well, sauerkraut, so I figure that’s okay?

The WB-06 starter did its thing – set up a krausen, bubbled, stopped. The yeast covering the surface is probably four times larger than what I started with. This isn’t a great degree of magnitude for a starter, and I don’t plan on stepping it up again.

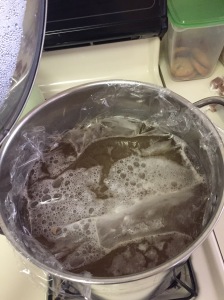

I fire up the kettle to get this bad boy reduced, hopped, and most importantly sanitized.  As discussed in the prior post, one of the great parts of kettle souring is that the only things that should touch your lacto culture are a piece of plastic wrap you’ll throw out and a stainless steel kettle that will spend an hour plus at boiling temperatures after encountering the bacteria. Heating up the kettle immediately sends the otherwise clear wort churning with all the break and trub. Most recipes I’ve read say to do a 90 minute boil, though none fully explain why, and many state that you’ll have to add water back in to hit a specific gravity. (*I’ve since read why and am now a bit nervous…) Hitting my fermentor volume is a trick I’ve been working on, so I estimate that a 75 minute boil will give me the volume I want and still way more than enough time to sterilize everything. This style usually doesn’t have much hops so I’ll just do a tiny charge at 60 and call it good. I was planning on using some Hallertau, but since I haven’t opened that package yet and this beer requires so little hops, I just toss in some Columbus I already had. Columbus is a pretty high alpha hop, so to hit 8 IBU I end up measuring out literally about three pellets.

As discussed in the prior post, one of the great parts of kettle souring is that the only things that should touch your lacto culture are a piece of plastic wrap you’ll throw out and a stainless steel kettle that will spend an hour plus at boiling temperatures after encountering the bacteria. Heating up the kettle immediately sends the otherwise clear wort churning with all the break and trub. Most recipes I’ve read say to do a 90 minute boil, though none fully explain why, and many state that you’ll have to add water back in to hit a specific gravity. (*I’ve since read why and am now a bit nervous…) Hitting my fermentor volume is a trick I’ve been working on, so I estimate that a 75 minute boil will give me the volume I want and still way more than enough time to sterilize everything. This style usually doesn’t have much hops so I’ll just do a tiny charge at 60 and call it good. I was planning on using some Hallertau, but since I haven’t opened that package yet and this beer requires so little hops, I just toss in some Columbus I already had. Columbus is a pretty high alpha hop, so to hit 8 IBU I end up measuring out literally about three pellets.

I pulled out the flask of WB-06 starter from the fridge, decanted off most of the “beer” from the starter, and set it near the stove to warm up. Towards the end of the boil I added in the last of the WB-06 packet to the flask to rehydrate. Hopefully between a starter that appeared to at least quadruple the cells from the salvaged and washed yeast from a prior batch, plus this fresh charge of dry yeast that had been opened for over a month and expired soon, we’d have a workable amount of yeast. Two less than reliable sources of yeast should equal a successful pitch rate. Also, this particular yeast is pretty hardy — it not only does well with higher temperatures, but it also does well when underpitched. Both factors will increase the banana-like esters produced by the beer, which are a quality I like in a brew, though maybe not usually found in a Berliner Weisse.

Anyway, back to the boil.

This beer smells weird. In addition to malt and sauerkraut, I get, like…cooked celery. My reading and the off-flavor class taught me the easy answer to that: Dimethyl Sulfides, or DMS for short. This is an element of beer wort that is fairly volatile and usually boils off. So since prior to this point in the process that beer had only been boiled 15 minutes, then was put into the oven while still warm (90 degrees) and there was condensation on the lid…well, some DMS was left in. Good news is we’re boiling the beer for a full 75 now, so we should cook all that grossness off. The wort hits a boil, the break starts to separate, hops in at 60. As the boil moves along, more weird smells show up. Usually the apartment takes on a pleasant brewery smell, and a hoppy smell when applicable, but this is bizarre. It smells like…barbecue sauce? I swear I just read someone on a forum having the same observation on a lactobeer, but I cannot for the life of me find it. I did, however, find this free 42 page off-flavor guide, which is super cool. I sanitize all my cold-side equipment. A bit later I give it another whiff, and it seems like a more normal wort-but-sour. After 75 minutes, flame off, into an ice bath, down to 70 degrees in 20 minutes. Wort gets funneled into the carboy, flask of yeast gets pitched, whole thing gets aerated. I can’t find my bungs (by the time of this writing I realized they were in the dishwasher…) so a plastic cap goes on, blowoff goes in, setup moves into the closet.

My ferm closet thermometer tells me the temperature near the twins is about 71 ambient and 64 underneath their evap-skirts. Nelson is still bubbling now and then and Sorachi is still, so I let the evap-skirts shrug down a bit in hopes of letting them rise to the high 60s to finish fermenting out.

At absolute worst this beer will acidify and take on terrible flavors until it is undrinkable and will infect that cap and blowoff and any airlock it uses until they have to be disposed. At next worse it’ll just have some butyric acid or DMS flavors from the early part of the process and be a gross beer. Somewhere between bad and good, this beer might have not soured at all and will just be a wheat beer, but based on all the olfactory signs thus far, that seems unlikely.

At best in two to three weeks this beer will have acidified down to around 3.8ph from its two days of lactobacillus contact, sterilized out any bacteria, taken off with the WB-06 yeast, fermented 68-71 ambient/70-75 fermenter, taken on a bit of esters without going into fusel or over-phenolic range, and finished into a nice, tart Berliner Weisse. If all tastes well on bottling day, I’ll maybe set a date to make a nice berry syrup for traditional serving.

Fingers crossed!! Prost!

Nice write up! Good luck with your Berliner, it sounds like it’s on just the right track. Btw, I wouldn’t worry about your boil length in regard to DMS concerns from Pilsner malt. The way I see it, you did boil for 90 minutes it was just broken up into two sessions. We do the same 15-75 minute split for our batches and have had very nice results. Cheers!

LikeLike

Thanks very much for the input! Here’s hoping for a good Berliner!

LikeLiked by 1 person